CMS for Hydro Turbines

RSL has successfully developed and installed a CMS system, the HT-HUMS, for Hydro-electric Power Plants (HPP). The HT-HUMS is a distributed hierarchal system which implements its machine learning and diagnostic and prognostic technologies for hydro-electric turbines power plants.

HT-HUMS Main Features

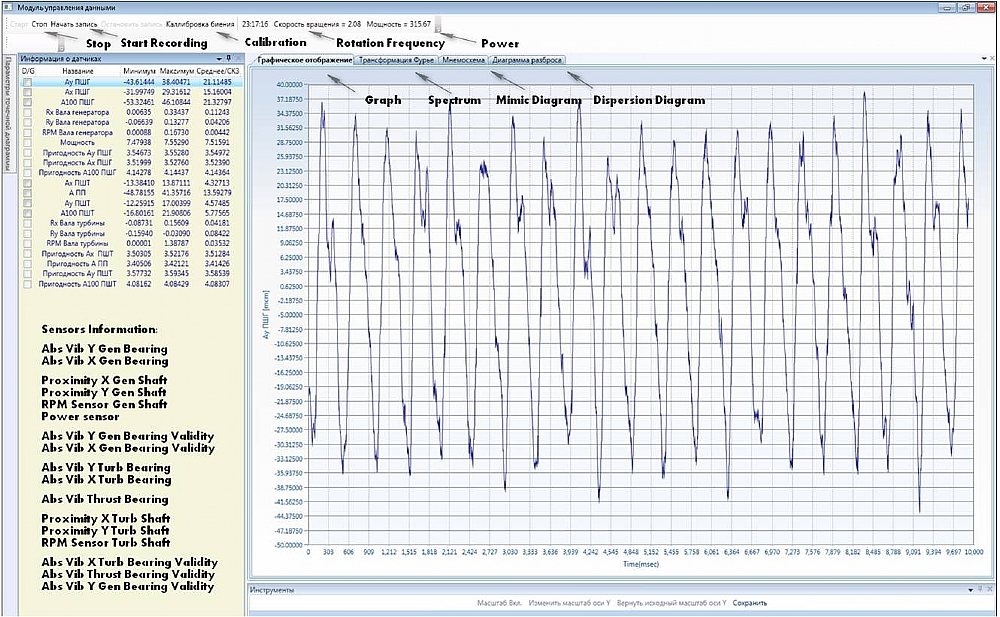

- The system's diagnostics, based on Learning Machine algorithms, accurately determines within the first few hours of operation the vibration alarm thresholds for each of the hydro-turbine components in addition to the OEM's set thresholds.

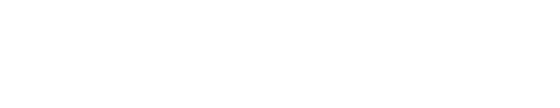

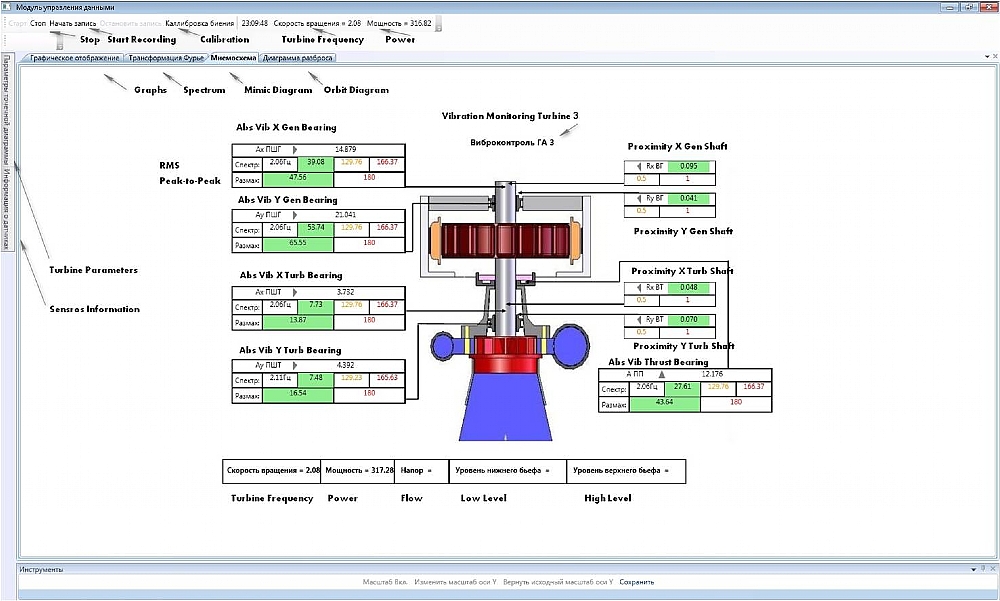

- Continuous real-time monitoring and diagnostics of the major hydro-electric turbine elements:

- Real-time alerts generation for operational anomalies, functional deterioration and failures.

- Storage of the raw and processed data as well as alerts history for referencing and in-depth analysis.

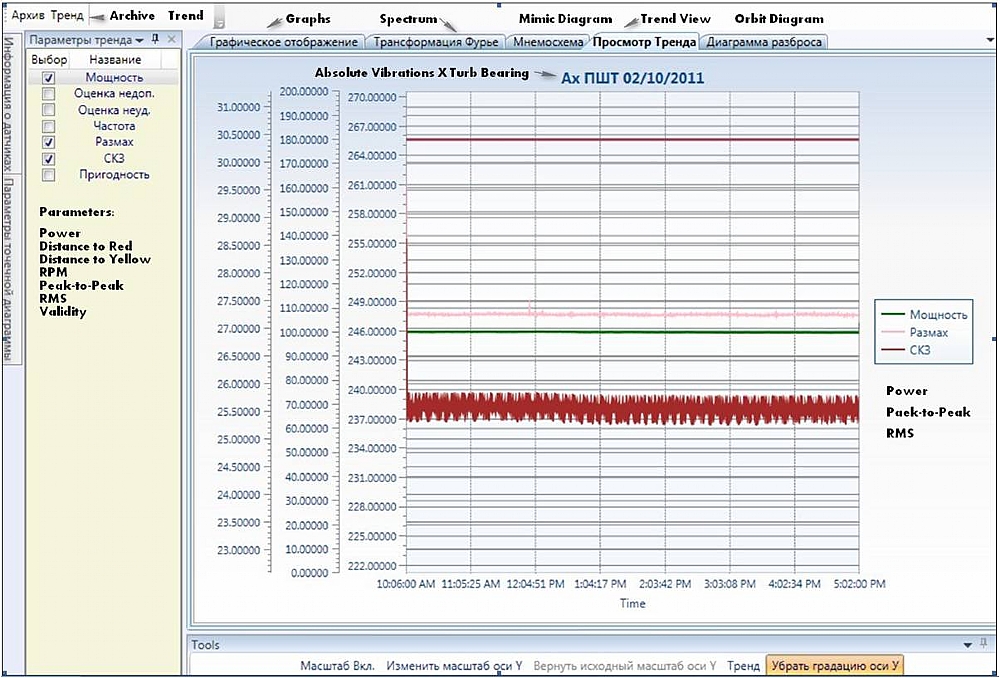

- Control room Graphical User Interface at the power station, allowing optional web based remote-access, which enables full visibility of the hydro turbine and electric generator health condition.

- Blade wheel – unbalance, wear, cracks.

- Main Shaft - imbalance, misalignment.

- Turbine Bearings – weakening, gap clearance, cooling.

- Generator rotor and stator – mechanical/electrical unbalance, air gap, stator core vibrations.

- Generator Bearings - weakening, gap clearance, cooling.

- Thrust bearing - irregularly distributed load, lubrication, surface damage.

HT-HUMS Benefits

- Increased availability by shifting from scheduled-based to condition based maintenance. Early fault detection enables maintenance planning prior to breakage and helps optimize maintenance outages.

- Reduction of Maintenance cost enabled by early fault detection which enables maintenance to be performed prior to breakage thereby eliminating secondary damages, unscheduled maintenance and optimizes spare parts management.

- Improved safe operation of hydro-aggregates by comprehensive real-time monitoring and diagnostics of turbine and generator vibrations.